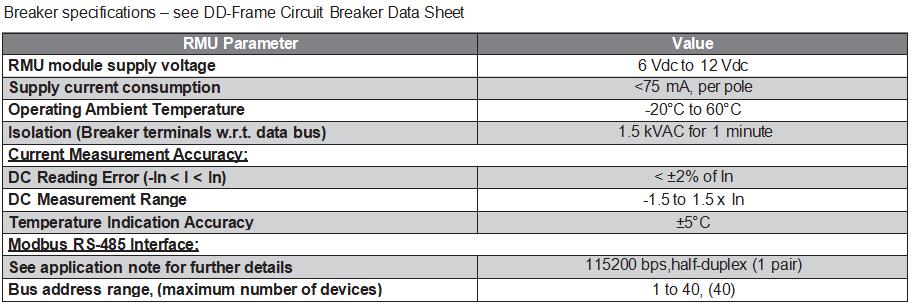

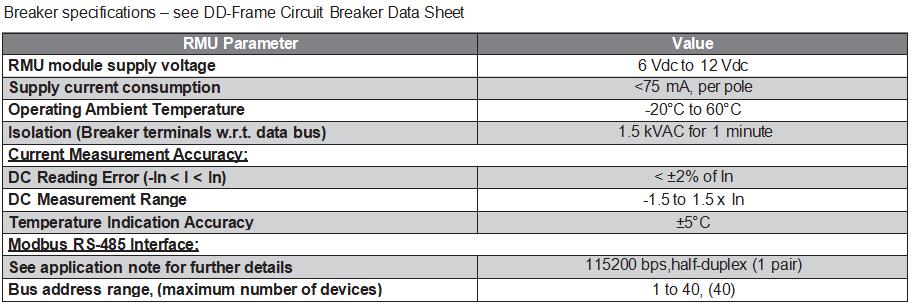

The RMU is a DD-Frame circuit breaker factory fitted with a remote monitoring unit (RMU) that measures the current flow and the circuit breaker’s condition, and communicates the information via a RS-485 serial bus. It enables the host system to monitor current usage and ON / OFF / Tripped contact status. The unit has an active health monitor for condition based maintenance, with the number of operations stored to memory (on-load, no-load and overload operations combined with operating conditions). Along with a readout of manufacturing information, each device has a unique ID number for traceability. It has RGB status LEDs, visible at the top and bottom, configurable for various status displays.

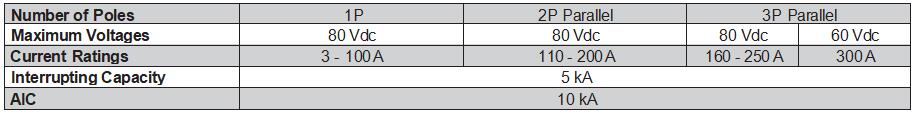

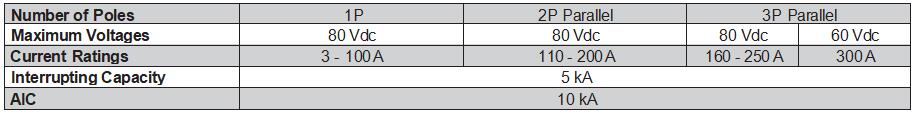

The RMU circuit breaker current range is from 3 A to 100 A on a single pole, up to 200 A on a double pole and up to

300 A on a three pole. The plug-in terminals are suitable for a hot-pluggable busbar style panel that includes a PCB strip with data connectors. The RMU modules self-identify their positions on the bus, based on a simple resistor scheme. The breaker footprint allows the panel to be backwards compatible with DD-Frame circuit breakers fitted with trip-alarm auxiliary, so that a panel can accomodate both RMU and standard breakers.

Features

• Intelligent Protection + Monitoring

• Real time status monitoring

• Circuit Breaker status (On, Off, Trip Alarm)

• Current measurement (Amps and direction of flow)

• Diagnostics (overload, temperature, operating hours, switching operation counters)

• Circuit Breaker Health Estimate* (percentage remaining life, based on operating conditions)

• LED indication of circuit breaker status. Visible top and bottom.

Configurable color scheme for RGB LED

• Automatic lamp test sequence while powering on

• Circuit breaker digital Information

Unique 64-bit ID for inventory traceability

• Current rating (and number of paralleled poles)

• Manufacturing date

• Ordering information

• Modbus over RS-485 data bus, up to 40 breakers on one serial bus

• Rear plug-in data terminal for simplified back-plane design

• Hot-swappable – inserted breakers self-identify on data bus

Applications

• Telecoms

• Dark Data Centers

• Digital Twin

• Condition Based Maintenance

• Energy optimisation

• Battery management